THE DIES

TOOL SHOP

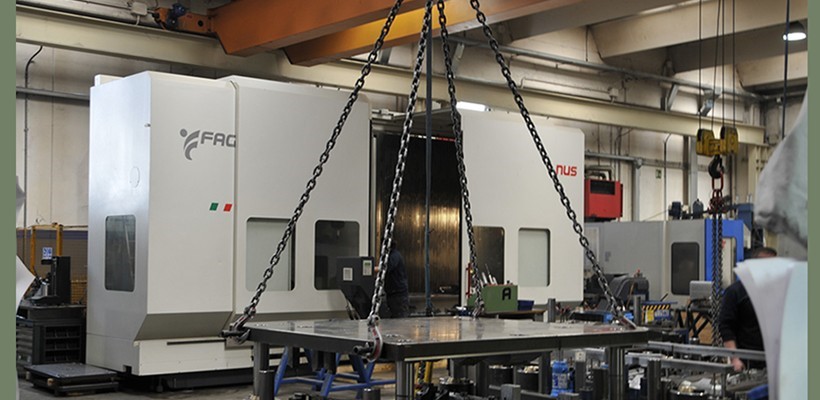

The qualified staff in our tool shop ensures the proper processing with high-performance CNC machines. We construct our high-quality products in the shortest possible time according to customer’s specifications and with competitive prices.

In order to improve the processing, we’re using the processing software from TEBIS for our simultaneous 5-axes milling machines. Every 5-axes program is able to simulate and analyze eventual collisions with the compounds of the machines. The simulation module from TEBIS has a virtual library with the description of every CN machine of our workshop.

Our machinery is fully equipped for the required work processes.

The working area is divided in two parts: one for the machining and another for the assembling and optimization of our tools.

Machining area:

- Fagima Dominus 5-axes milling machine in continuous operation (3000x1000x1200);

- Sachman (3000x1400x1200);

- 5-axes high-speed milling machine Fagima Spin Fast (2220x700x600);

- Wire EDM machine Sodick.

Assembling and optimization area:

- Hydraulic press Emanuel 300 T with die cushion;

- Try-Out-press

- Crane with load capacity from 5 tons up to 10 tons;

- Forklift trucks up to 8 t load capacity;

- Other machines like traditional milling machines, turning lathe, grinding machines, sews, shot blasting machine, furnace for surface treatment etc.

- CNC-measuring machine COORD 3.

Another area in our tool shop is reserved for the maintenance of the tools of our clients. This supplement service warrants the unobjectionable quality of our products even after the stress of many production cycles.